Imagine this: You’re on a bustling construction site, the air thick with the scent of concrete and the rhythmic roar of machinery. You’re about to pour the foundation for a new home, a vital step in bringing dreams to reality. Suddenly, a dreaded clunk and a grinding halt – your Red Lion Big Cat cement mixer has come to a standstill! The project grinds to a halt, and you’re left wondering what went wrong and how you’re going to get back on track.

Image: mungfali.com

This scenario can be a contractor’s worst nightmare. But fear not! Understanding your Red Lion Big Cat cement mixer parts list is your key to unlocking peace of mind and keeping your construction projects running smoothly. This guide will take you through the essential components of your mixer, explaining each part’s function and highlighting the importance of regular maintenance and troubleshooting.

Delving into the Heart of the Machine: Understanding the Red Lion Big Cat Cement Mixer Parts List

The Red Lion Big Cat cement mixer, a robust workhorse in the construction industry, relies on a complex interplay of parts to perform its crucial task. These parts work together flawlessly to mix, transport, and deliver concrete efficiently. Let’s break down the key components of this crucial machine:

1. Drum: The Mixer’s Mighty Core

The drum, the defining element of any cement mixer, is where the magic happens. This large, rotating cylinder, usually made of durable steel, is responsible for the thorough blending of cement, aggregates, and water. The drum’s internal design, often featuring fins or baffles, ensures a consistent and homogenous concrete mix.

- Types of Drum Designs: You’ll find different drum designs, including open-end drums for easier loading and discharge, or closed-end drums for increased mixing efficiency. Understanding which design your Red Lion Big Cat mixer has is essential for selecting the right replacement parts.

2. Drive System: Powering the Mixer’s Might

The drive system is the powerhouse behind the drum’s rotation. It typically includes a powerful motor, a gear reduction unit, and a chain or belt system to transfer power.

- Understanding the Drive System: A well-maintained drive system ensures consistent rotation speed and prevents premature wear and tear. Regular inspections and lubrication are critical.

Image: mixercrot.netlify.app

3. Hopper: Feeding the Mix

The hopper is the central point where the raw ingredients – cement, aggregate, and water – are poured into the mixer. It features a wide-mouth design for easy loading and a secure locking mechanism to prevent accidental spillage during operation.

- Proper Hopper Maintenance: Keep an eye out for any cracks or damage to the hopper, as these can significantly impact the mixing process and safety.

4. Water Tank: The Perfect Hydration

The water tank is responsible for providing the precise amount of water required for a successful concrete mix. It usually comes equipped with a gauge and a valve for controlled water addition.

- Ensuring Proper Water Delivery: Make sure the tank is free of leaks and that the valve operates smoothly to prevent over-watering, which can compromise concrete strength.

5. Chassis: The Foundation of Strength

The chassis, the sturdy foundation of the cement mixer, houses all the critical components and provides stability while in operation. It’s constructed from heavy-duty steel and designed to withstand the rigors of construction sites.

- Strengthening Your Chassis: Look out for any signs of fatigue or damage to the chassis, as these can compromise its structural integrity and lead to safety hazards.

6. Tires and Wheels: Navigating the Construction Site

The tires and wheels allow for easy maneuvering of the cement mixer across the construction site. Durable and reliable tires are essential for navigating challenging terrain and heavy loads.

- Tire Maintenance: Remember that proper tire pressure and tread depth are crucial for safe operation and can significantly impact fuel consumption.

7. Controls: Keeping Your Mixer Under Control

The control panel provides the operator with the necessary levers and switches to manage the machine’s functions. These controls allow for starting and stopping the motor, adjusting the drum’s rotation speed, and accessing safety features.

- Understanding the Controls: Familiarity with the control panel is crucial for operating the mixer safely and efficiently.

Navigating the Red Lion Big Cat Cement Mixer Parts List: Essential Components

Now that we’ve explored the essential components let’s delve deeper into the specific parts that make up the Red Lion Big Cat cement mixer. Identifying the correct parts is essential for repairs and replacements:

-

Drum Assembly: The heart of the mixing process, the drum assembly consists of the drum itself, supporting rollers, and a drive shaft. These components should be inspected regularly for wear and tear.

-

Motor: The motor drives the drum, powering the entire mixing process. Ensure your motor is in good working condition and lubricated properly for smooth operation.

-

Gearbox: The gearbox reduces the motor’s speed to a more efficient rotation rate for the drum. Keep an eye on oil levels and ensure the gearbox is operating smoothly.

-

Chain or Belt Drive: The chain or belt drive system transmits power from the motor to the drum. Regular inspection and replacement of worn or damaged chains or belts are essential.

-

Hopper: The hopper should be inspected for cracks, damage, and leaks. Replace any defective parts.

-

Water Tank and Valve: The water tank, valve, and associated piping should be regularly inspected for leaks and proper operation.

-

Chassis: Check the chassis for any signs of fatigue, cracks, or damage. This is crucial for structural integrity and safety.

-

Tires and Wheels: Ensure your tires and wheels are in good condition, with proper tire pressure and tread depth.

-

Control Panel: Inspect the control panel for any damaged controls, switches, or wiring.

Beyond the Parts List: The Importance of Maintenance and Troubleshooting

Understanding the Red Lion Big Cat cement mixer parts list is just the first step. Taking the time for regular maintenance and learning basic troubleshooting techniques can dramatically extend the life of your equipment and minimize downtime.

Essential Maintenance Tips:

- Regular Inspections: Set aside time for routine inspections of all parts, even those seemingly in good condition. Early detection of wear and tear can prevent more serious problems.

- Lubrication: Proper lubrication of the drive system, gearbox, and moving parts is essential to reduce friction and extend component life.

- Cleaning: Keep the mixer clean and free of debris, especially the drum and hopper, to prevent clogging and ensure optimal performance.

- Follow the Manufacturer’s Recommendations: Consult your Red Lion Big Cat cement mixer’s user manual for specific maintenance recommendations and service intervals.

Troubleshooting Tips:

- Listen for Unusual Noises: Unusual sounds, like grinding, screeching, or clunking, can be early indicators of a problem. Stop the mixer immediately and investigate.

- Check Fluid Levels: Ensure the motor and gearbox have the correct oil levels. Low fluid levels can lead to overheating and damage.

- Inspect Belts and Chains: Visually inspect belts and chains for wear, damage, or slippage. Replace any worn or damaged parts.

- Test the Controls: Make sure all controls are responsive and functioning correctly.

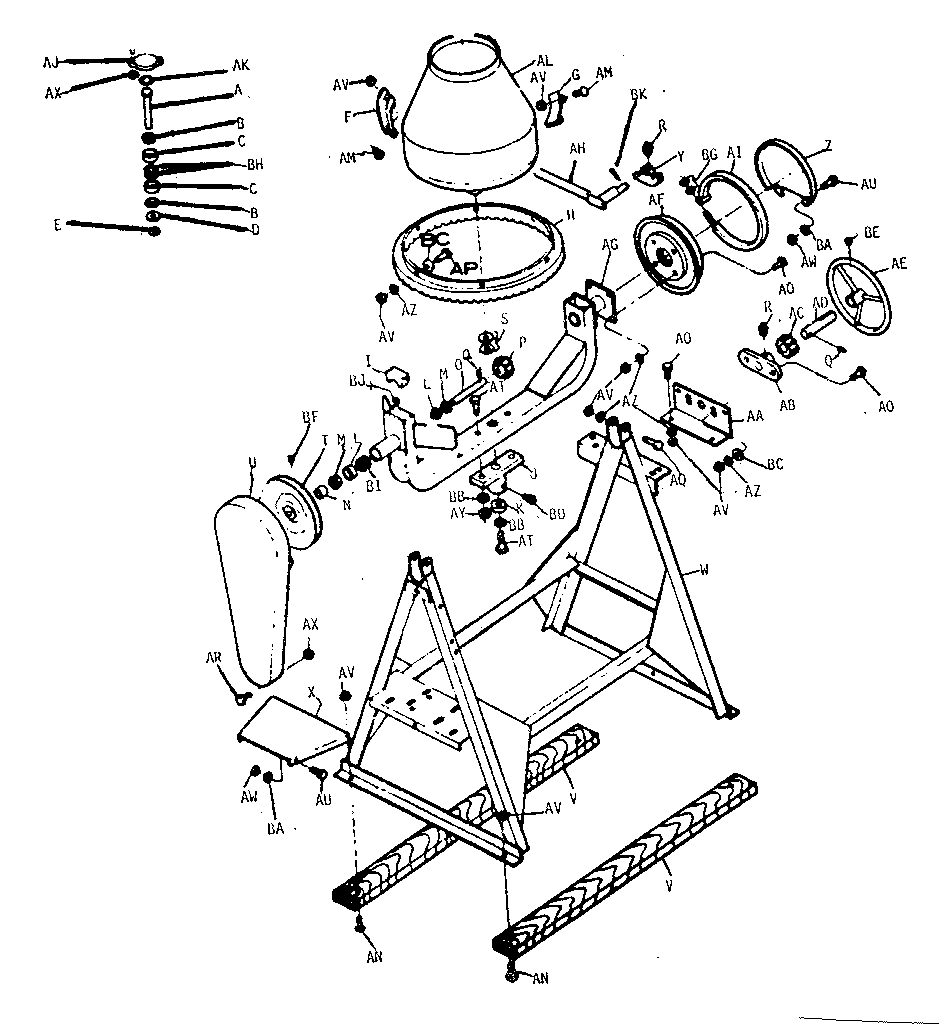

Red Lion Big Cat Cement Mixer Parts List

Leveraging Your Knowledge for Success

By understanding the Red Lion Big Cat cement mixer parts list and prioritizing regular maintenance and troubleshooting, you’ll have the confidence to keep your machine running smoothly and efficiently, allowing you to focus on completing your projects on time and within budget. A little bit of preventative care can go a long way in extending the life of your equipment and ensuring your projects stay on track.

Remember, the key to success lies in staying proactive and armed with knowledge. Invest the time to learn more about your Red Lion Big Cat cement mixer, and you’ll be rewarded with a reliable machine that will help you achieve your construction goals.